Testing and Inspections

We have all equipment and devices necessary for inspections and testing.

We have developed on line grinder Ultrasonic Inspection Machines, which efficiently detects harmful defects without affected by the small change in magnetization of rolls.

Such machines are available to be supplied to our customers.

Inspection Item | Equipment |

|---|---|

Chemical Composition Analysis | Optical Emission Spectrometer, Leco meter |

Hardness | Shore D Scale, HLD and HLE |

Residual Stress | X-Ray Residual Stress Equipment |

Ultrasonic Inspection | After Rough Machining |

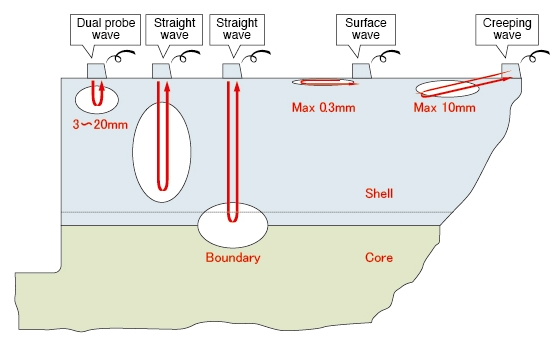

Outline of Ultra Sonic Test

For quality assurance of shell, we carry out following 4 kind Ultra Sonic Test. The effective inspection thickness of each method is deference.

Surface wave | effective inspection thickness is from surface to about 0.3mm. |

Surface wave and creeping wave are carried out by automatic ultrasonic test.

Dual probe wave and straight wave are carried out by manual ultrasonic test.