Rolls must be capable of consistently rolling the highest quality steel products, meeting even harsh operating requirements such as those for wear resistance, surface roughening resistance, and toughness. Rolls must also have long service lives.

Casting products have the advantages of (1) high flexibility in shape and size, (2) high flexibility in materials, and (3) excellent recyclability and environmental friendliness, but casting faces difficulties, including the appearance of defects such as inclusions and blowholes.

Though the metalworking technology of casting is thought to have begun in pre-Christian times, in addition to the fact that requirements for casting products are becoming more advanced, the materials used and manufacturing methods are also changing, so it is necessary to continue to evolve (deepen) quality design and manufacturing technology to ensure stable quality and to continuously improve quality.

We always seek the optimal quality design and manufacturing technology based on information such as customers' usage results and needs as well as production/equipment conditions and inspection results during roll manufacturing.

At the manufacturing site, we work to improve our on-site capabilities to safely and stably produce the highest quality rolls.

Manufacture and quality design of high-quality rolls that meet various needs by freely manipulating castings, which are sometimes called living things.

The experience and responsiveness cultivated by our tradition as Japan's first roll manufacturer.

With the goal of becoming the world's number one roll manufacturer, a rich imagination and the development capability to realize products that meet the demands of the times.

The sense of responsibility and craftsmanship of each individual, and the sense of unity that comes from working together to produce a single roll.

Developing the skills of our people by making full use of their intuition and ingenuity in addition to their experience.

Our rolls are manufactured using processes that comply with JISQ9001:2015 (ISO9001:2015).

Nippon Steel Rolls won the Okochi Memorial Production Prize for the development of a high-speed steel (HSS) rolling mill roll employing the continuous pouring process for cladding (CPC roll)

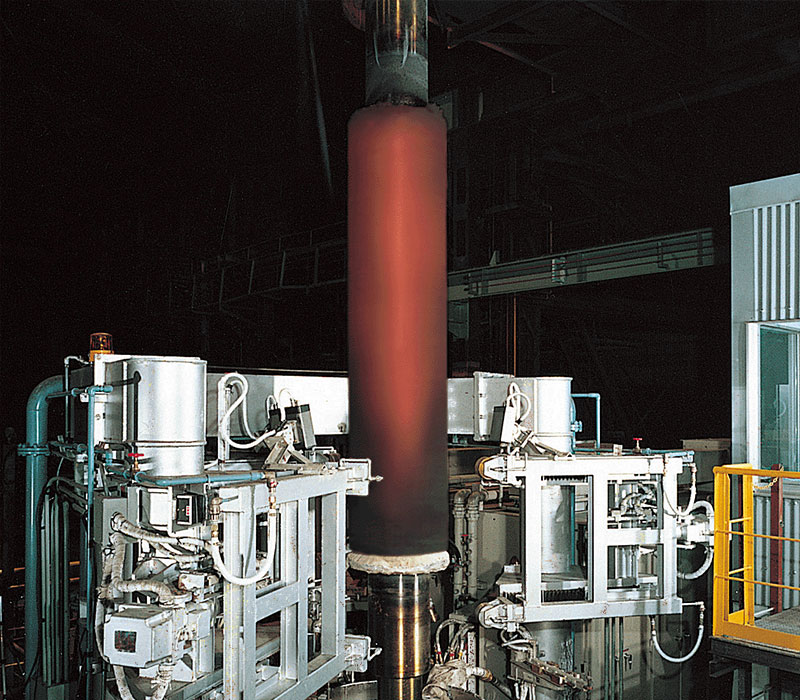

In 1990, we developed CPC(Continuous Pouring Process for Cladding)HSS rolls that are extremely resistant to wear and surface roughening and that have an extremely high level of toughness.

Compared to conventional rolls, CPC HSS rolls are approximately five times more resistant to wear, four times more resistant to surface roughening, and have a toughness two times greater, demonstrating highly superior performance, and have brought about a revolutionary advance in the rolling process of steel manufacturers. In addition to improving the dimensional accuracy and surface quality of rolled products, rolling operation efficiency and inventory management efficiency have been dramatically improved by greatly reducing the rolling restrictions imposed by the rolls.

In recognition of these achievements, the CPC HSS rolls developed by our company won the Okochi Memorial Production Prize in 1998. The Okochi Memorial Production Prize is a prestigious award commemorating the achievements of the late Dr. Masatoshi Okochi. It is awarded by the Okochi Memorial Foundation to individuals, groups, and business entities that have significantly contributed to the advancement of science and the development of industry in Japan through research in production engineering, advanced production methods, and related fields.

The CPC HSS roll is a high-performance composite roll that employs a special manufacturing method in which a material (molten metal) with excellent wear and surface roughening resistance is continuously cast and welded onto a strong steel core. Because of the intricacy of the method, a great deal of effort and time was required to establish this roll as an industrial product based on equipment specifications, material design, operating conditions, and so forth. Of course, this also required the cooperation of the steel manufacturers who use the rolls.

As a result of the concerted efforts of all parties involved to overcome these many challenges, we have been able to develop and manufacture CPC HSS rolls that are far superior to conventional high-alloy grain cast iron rolls. Our CPC HSS rolls are now highly regarded by many customers in Japan and overseas, including Nippon Steel Corporation, and are used all over the world.

here